News and Events

Derek Whelpton obituary.

[16/02/2026]

We received the sad news of the passing of our former Managing Director, Derek Whelpton, at the age of 83.

Investment continues at DSF.

[11/02/2026]

Investment continues at DSF during National Apprenticeship Week.

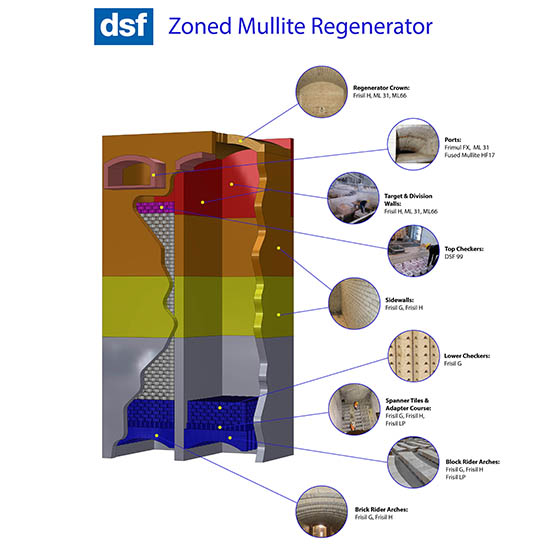

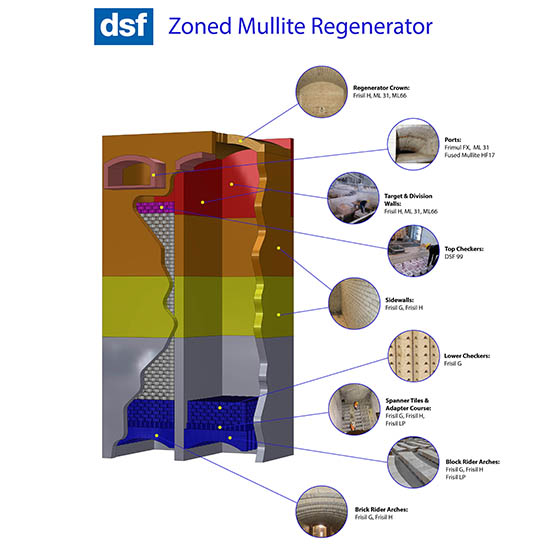

DSF Mullite ML66

[20/01/2026]

DSF Mullite ML66, the latest addition to our portfolio of products for the glass industry

Weighbridge Christmas Opening Hours

[11/12/2025]

Weighbridge Timetable for Monday 22nd December - Monday 5th January

Processed minerals sales

[04/12/2025]

At DSF we offer raw materials for refractories, high friction surfacing, ceramics and anti-slip applications.

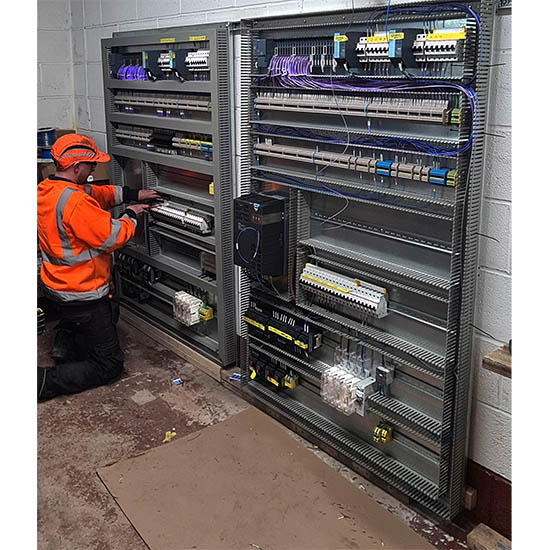

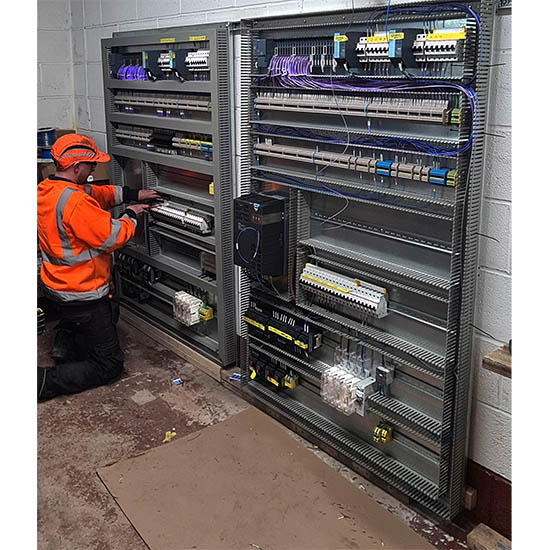

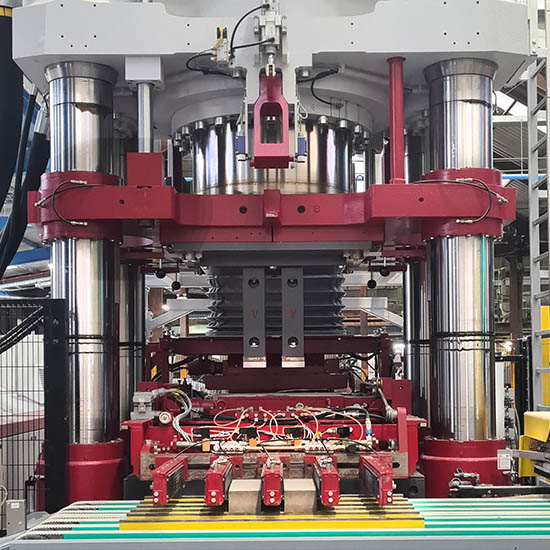

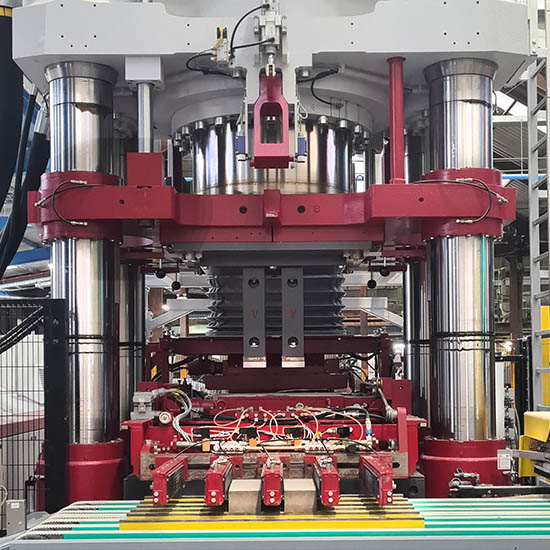

New Automatic Refractory Brick Press Commences Operation

[13/11/2025]

A collaborative partnership between DSF and Siemens, founded on trust, hard work, and diligence, has successfully delivered a project three years in the making.

DSF supply Guyanan RASC Bauxite for large bridge project

[13/11/2025]

DSF’s Guyanan RASC Bauxite was chosen to complete the road surface due to its high friction and superior anti-slip properties.

Ceramic Industry, Pledge Conference & Awards

[10/10/2025]

DSF Wins Awards at the 25th Anniversary of the Ceramic Industry, Pledge Conference & Awards.

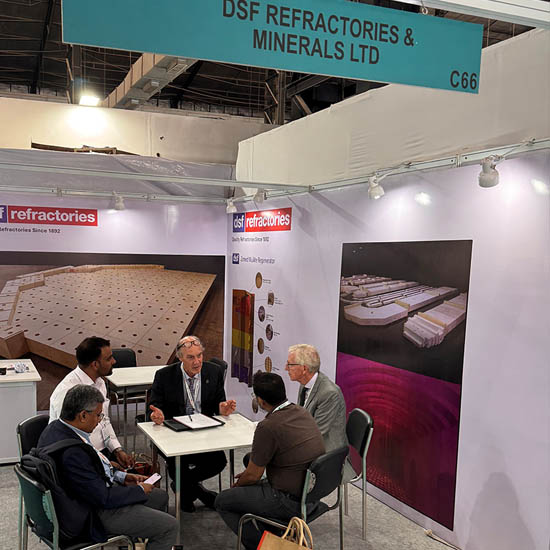

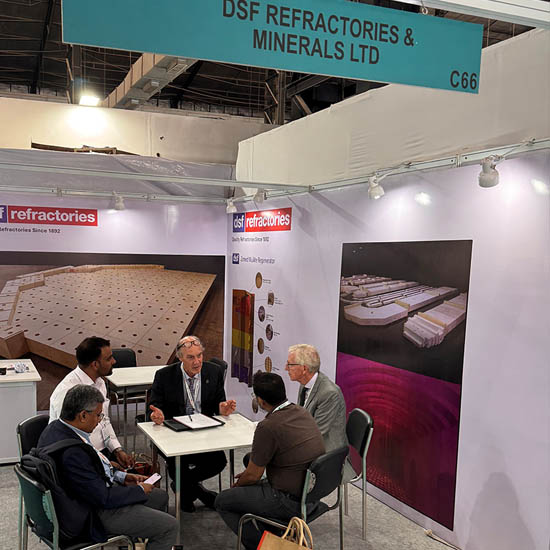

Glasspex India 2025

[15/09/2025]

Thank you to everyone who came to our stand at Glasspex India last week.

New Covered Storage Bins

[29/07/2025]

Work is almost complete at DSF on new covered storage bins.

VR Day at DSF

[02/07/2025]

Employees view a 3D simulation of our new LAEIS refractory brick press.

DSF’s Guyanan RASC Bauxite has many uses

[30/06/2025]

Guyanan RASC Bauxite recently spotted on the Wainwright’s Coast-to-Coast path.

SANDS chosen as 2025/26 charity

[22/06/2025]

DSF is proud to have chosen Sands, Stillbirth and Neonatal Death Society, as it’s 2025/26 charity.

Site investment at DSF

[22/05/2025]

Work is well under way on the installation of a new hydraulic press.

Biofuel trial successfully completed at DSF

[04/05/2023]

DSF are evaluating alternative fuels for firing refractory materials.

DSF's visit to Parliament

[01/02/2025]

DSF's Managing Director Paul Hutchinson visits the House of Commons.