Carbon Black

DSF offer a complete range of refractories for tread and carcass reactors. High purity alumina materials are supplied in machine pressed and vibratory cast versions. DSF also supply unique magnesia-alumina spinel materials, which can potentially give our customers operational advantage.

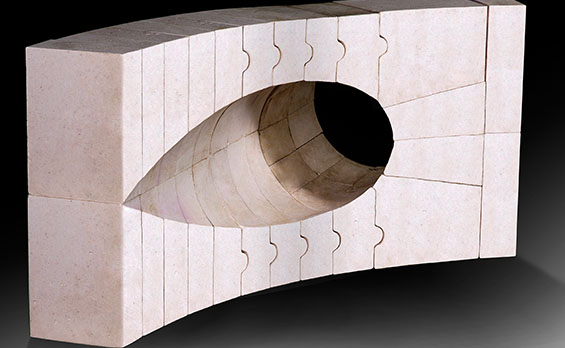

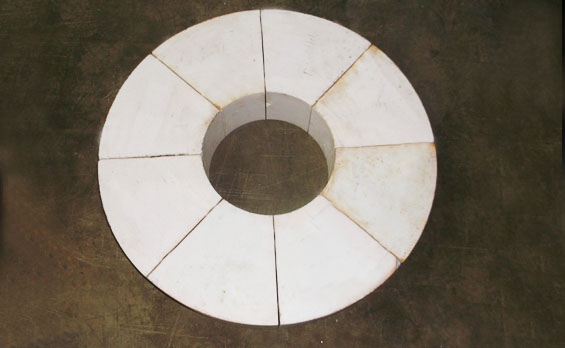

Two high purity alumina materials are manufactured at DSF for carbon black reactors; DSF 99 for pressed arch bricks and DSF 99C for complex or larger shapes. Both these materials are fired to 1700°C and are used to withstand the reducing conditions and high temperatures inherent in the carbon black process. Complex shapes are difficult to produce as traditional casting methods use cement or ethyl silicate, which limit maximum operating temperature in the reactor. At DSF we utilise special no cement casting technology where only alumina is used to cast complex shapes. The ability to use complex or large shapes instead of trying to cut and make pressed bricks fit, reduces installation time and improves joints.

DSF also offer a magnesia-alumina spinel material, DSF Frimax 7, which can withstand higher temperatures than a conventional alumina lining. DSF manufacture both cast and pressed spinel materials, high fired to 1700°C but with a melting point of approximately 2135°C. In reactors where high purity feedstock is used, Frimax spinel can potentially significantly increase operating temperature of the reactor giving better yield and better quality product. DSF Frimax 7 is the pressed version and DSF Frimax C is the cast version used to produce complex or large shapes. Thermal shock resistant versions are also available, DSF Frimax HI and DSF Frimax CHI. In the tread reactor, a thermal shock resistant pressed material (DSF 92Z) can be used in the water quench section.

A range of monolithic and insulating materials are supplied to customers who may wish to purchase the full package. DSF also have the capability to provide installation and/or refractory supervision in the carbon black industry, along with manufacturing drawings.